Listo, ya tienes tu máquina, ya tienes a tu asistente o encargado del área de sublimación y empezaron a trabajar. ¿Cuál es el siguiente paso?, bueno... Trabajar bastante, en este momento te toca aprender todos los pros y contras de la sublimación y esos detalles que se aprenden en la práctica. Pero como siempre queremos ayudar y contribuir con esa parte te daremos los que entendemos que son los 4 principales detalles o factores que debes tener en cuenta al momento de la sublimación.

- El material: así como lo lees, siempre debes asegurarte de que estas trabajando con los materiales correctos al iniciar la sublimación, con esto queremos aclararte, la sublimación consiste en transferir una tinta sobre una superficie de plástico, principalmente poliéster, por este motivo, es de suma importancia que tus materiales sean los adecuados para la sublimación, porque sino, no vas a obtener ningún resultado apropiado, ¿Cómo cuales? Diseños que no serán permantes, acabados opacos o simplemente no pasarse la sublimación.

- La temperatura: entiendo que esta parte puede sonar confusa, porque en el blog anterior ya te presentamos las temperaturas que recomendabamos para los distintos materiales, pero debes tener en cuenta que estas pueden variar según el equipo y según el usuario. Es decir, que te dirán muchas temperaturas, debes tomar la que es mejor para ti, y esto lo lograrás a través de la practica. Si un diseño te queda muy claro, o no se aprecian suficiente los colores, es la temperatura que no es la apropiada. PERO CUIDADO una temperatura demasiado alta puede dañarte el material y quemarlo.

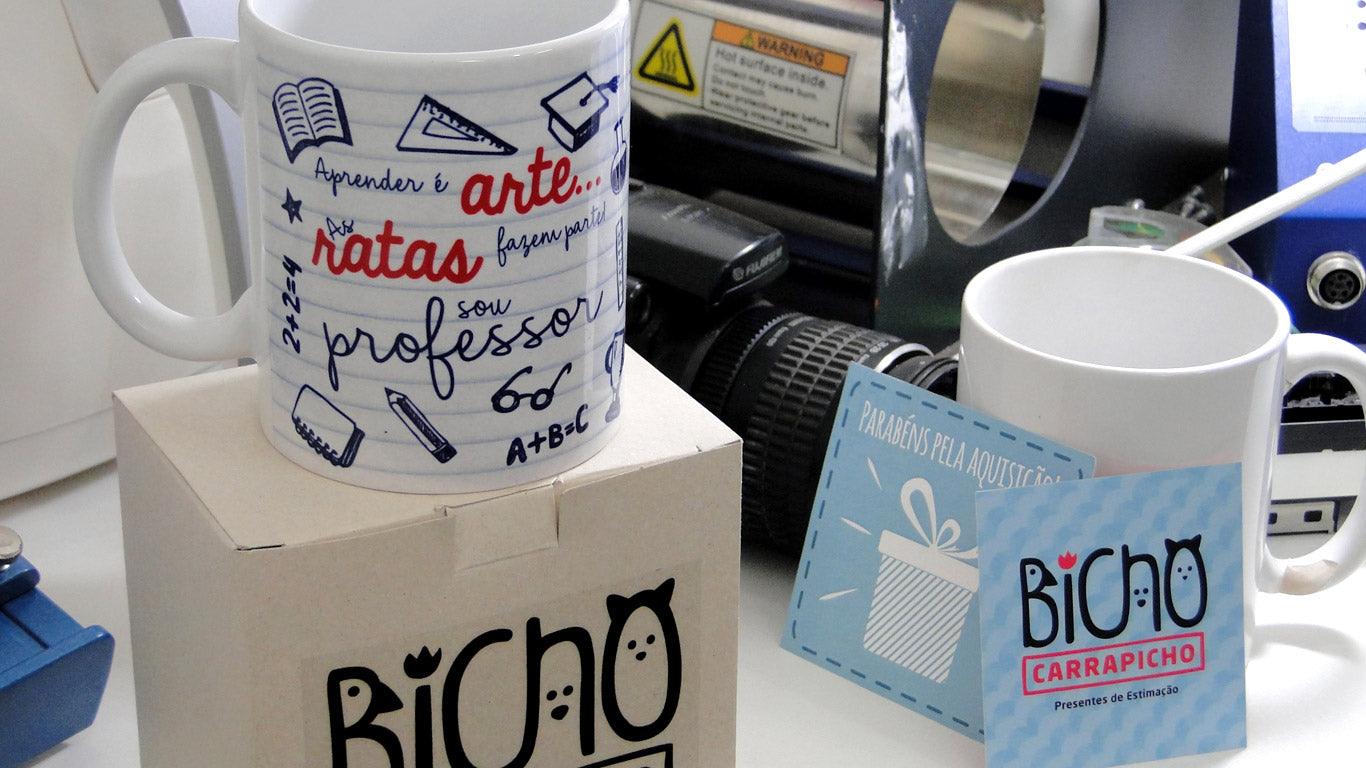

Este es un ejemplo de una taza que fue planchada y no se obtuvo el mejor resultado, esto se debe a que la temperatura estaba muy baja y no pudo pasar el diseño de la forma apropiada.

- El tercer factor a tener en cuenta, es la presión: si no estás dandole la presión apropiada al material este no podrá hacer el proceso de transferencia y al igual que el caso anterior quedará super claro, y notarás como queda el diseño en el papel, así que, fijate siempre en la presión, ¿Cómo medirla?, que debas realizar un nivel de esfuerzo al cerrar tus equipos pero no demasiado que puedas romper la pieza. En el caso del papel transfer si no tiene la presión apropiada, al concluir el dibujo se va a remover, esto pasa igual con el vinil textil.

- Y el último, pero no menos importante, es el tiempo: si te sobrepasas, al igual que con la temperaturas puedes quemar el resultado, y le das muy poco puede que la transferencia no se haga completa o no se termine de adherir el resultado.