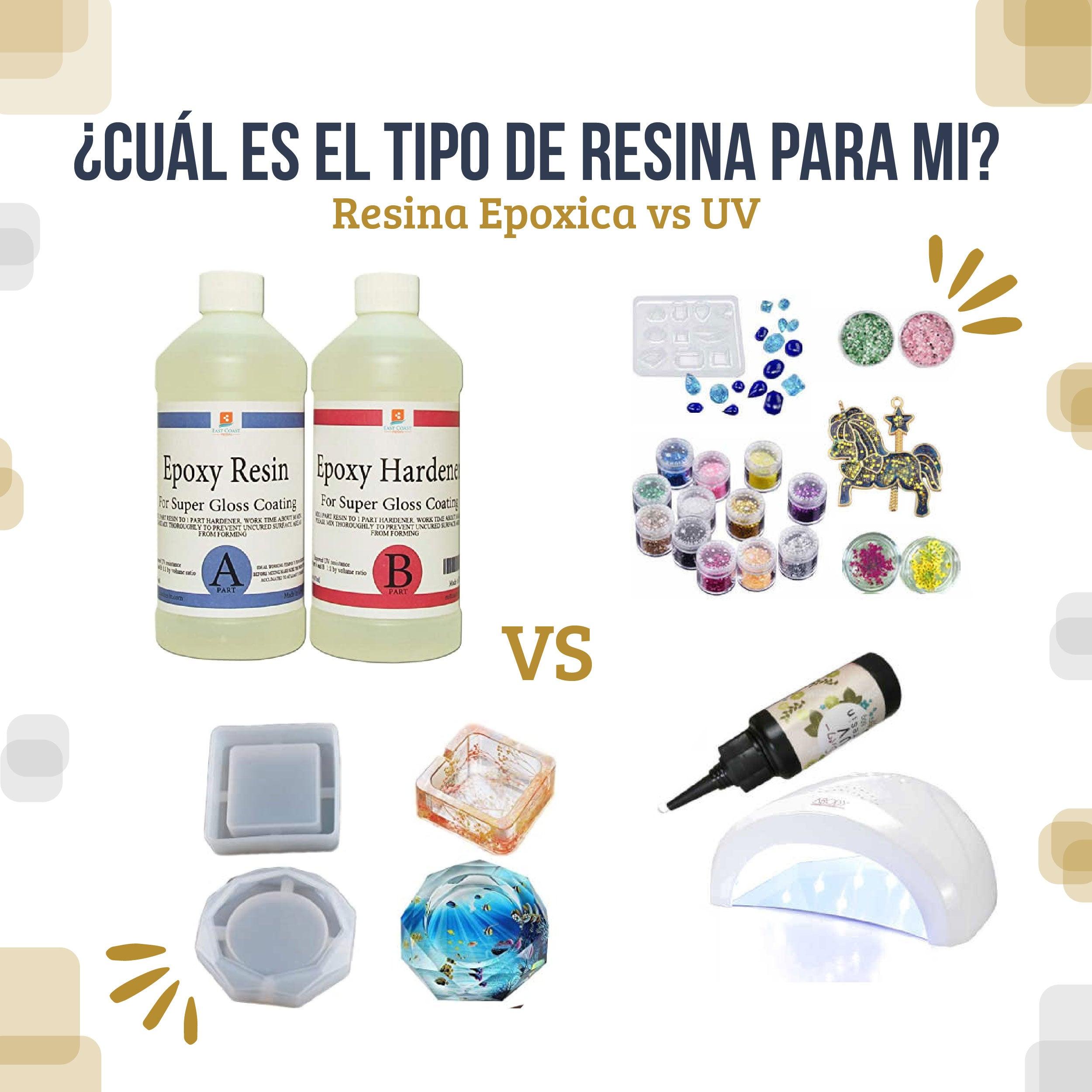

Esta es una pregunta que nos puede surgir al momento de trabajar con estos materiales, ¿Cómo podemos decidir cual es la indicada para nosotros? ¿A cuál le daremos el mejor uso?

Tenemos la conocida Resina Epóxica, como ya sabemos, es tipo de plástico termoestable, que se transforma de estado líquido a sólido cuando se aplica un endurecedor. Pero conociendo esta resina, ¿Cuáles son sus ventajas:

- Nivel de transparencia

- Durabilidad

- Combinación con gran variedad de materiales

Entre sus desventajas tenemos:

- Baja resistencia a los rayos UV.

- Necesita mezclar la composición

- Largo período de secado.

¿Qué piezas podemos trabajar con esta resina?

- Combinar materiales

- Crear piezas de gran tamaño

- Obtensión de acabados transparentes.

- Piezas de pequeño tamaño

Por otro lado, tenemos la Resina UV, es un tipo de resina que como su nombre lo indica realiza el proceso de curado utilizando una luz UV. Esta resina se utiliza para manualidades de pequeño tamaño. Entre sus principales ventajas tenemos:

- Rápido secado

- No necesita mezclarse

- Por su rápido secado funciona como pegamento.

También tiene sus desventajas, como:

- Debe tenerse cuidado al momento de su aplicación para evitar burbujas.

- No se recomiendan capas muy gruesas porque no puede secar propiamente.

¿Qué trabajos podemos trabajar con esta resina?

- Piezas de pequeño tamaño

- Joyería y Bisutería

- Utilizarla de pegamento entre otras resinas

La siguiente resina, es la Resina de poliuretano, o la conocida como "Resina blanca", esta resina esta compuesta de poliuretano, por lo que al momento de realizar la mezcla, normalmente 1:1, toma un colocar blanco. Entre sus ventajas tenemos:

- Baja densidad, es decir, menos burbujas.

- Rápido secado

- Resistencia a los rayos UV

- Se puede pintar.

Las desventajas que presenta son:

- No es tan dura como la epoxica

- Desgasta los moldes debido a su nivel de densidad.

¿Qué trabajos podemos trabajar con esta resina?

- Piezas de pequeño tamaño

- Joyería y Bisutería

- Piezas decorativas para muebles

Y por último, tenemos Resina de Poliéster, es un tipo de resina que cuenta con un endurecedor, a diferencia de las anteriores requiere una cantidad de 1-3% de endurecedor con respecto a la cantidad total de resina. Es la más económica pero al mismo tiempo la más tóxica.

Sus principales ventajas son:

- Bajo Costo

- Rápido Secado

Desventajas:

- Fuertes olores

- Color gris

¿Qué trabajos podemos trabajar con esta resina?

- Piezas Huecas, debido a su rapido secado logra adherirse a los moldes.

- Reparación de piezas industriales.